Can Phenolic Paper Laminate Resist Chemical Corrosion?

2024-07-24 15:23:49

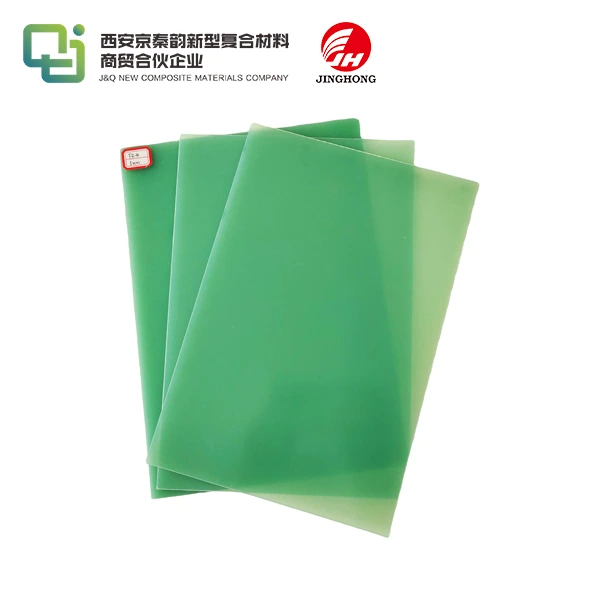

In addition to its remarkable resistance to chemical corrosion, phenolic paper laminate is highly regarded for its exceptional insulating properties, mechanical toughness, and longevity. It is the material of choice because chemical exposure is a concern in many industrial applications.Because of how it is made, chemicals cannot harm the phenolic paper laminate. This laminate typically develops a structure that is dense and compact when layers of paper are coated with phenolic resin and then subjected to high pressure and temperature for the purpose of curing. The underlying materials are effectively shielded from chemical attack by this structure, maintaining their functionality and integrity over extended periods of time.With dependability, phenolic paper laminate resists solvents, acids, alkalis, and other corrosive substances. Because it is resistant to deterioration and does not easily deteriorate, it maintains its long-term performance even in harsh environments. Oil and gas, marine designing, substance handling, auto fabricating, and auto producing all depend on parts that can endure unforgiving synthetic conditions without compromising wellbeing or proficiency.Additionally, the inactive design of the phenolic paper cover aids in substance obstruction. Chemical reactions that could weaken or compromise the material's structure are avoided because it does not react with most chemicals. Because it is stable, more dependable, and requires less maintenance, it is a cost-effective option for applications where durability and longevity are important.To conclude, the phenolic paper overlay's resistance to compound consumption demonstrates its adaptability and dependability in a variety of contemporary settings. It is the material of choice for critical components and systems that are exposed to challenging chemical environments due to its robust mechanical strength, excellent insulating properties, and superior chemical resistance.

What Makes Phenolic Paper Laminate Chemically Resistant?

Layers of paper are impregnated with phenolic resin and carefully cured under controlled heat and pressure to produce phenolic paper laminate. Its remarkable resistance to chemical corrosion is primarily due to its unique composition and manufacturing process.

The laminate's durability and resistance to chemicals are significantly enhanced by the phenolic resin. By shaping a thick framework within the paper layers, it successfully encases the filaments and creates major areas of strength for and against compound specialists. Acids, solvents, alkalis, and other corrosive substances are prevented from passing through the material and causing degradation by this barrier mechanism.

The inherent inertia of the freed phenolic sap toward other synthetics also contributes to the overlay's resistance. Chemical reactions that could eventually compromise the material's structural integrity or functional properties must be avoided first. Even in harsh industrial settings where chemical exposure is common, phenolic paper laminate maintains its performance and dependability due to its stability.

Due to its resistance to chemical attack, the laminate is ideal for a wide range of applications in a variety of industries. Which is chosen for its demonstrated capacity to provide long-lasting protection and maintain operational efficiency in industries such as chemical processing, automotive manufacturing, electrical engineering, and marine applications, where components are exposed to aggressive chemicals.

In a nutshell, the phenolic paper laminate's exceptional chemical resistance is due to the combination of phenolic resin-impregnated paper and a heat-and-pressure-cured process. Because of this quality, it is the material of choice for critical applications that require dependability, durability, and resistance to chemical corrosion. In addition to its mechanical strength and electrical insulation properties, this quality exists.

How Does Phenolic Resin Contribute to Chemical Resistance?

The primary reason for the chemical resistance of phenolic paper laminate lies in the properties of phenolic resin. Phenolic resins are highly cross-linked polymers that create a dense, thermosetting network when cured. This network structure is highly stable and resistant to chemical attack. When exposed to corrosive chemicals, the tightly bonded molecular structure of the phenolic resin prevents the chemicals from penetrating and degrading the material. This stability makes an excellent choice for environments where chemical exposure is a concern.

Comparative Analysis with Other Materials

When compared to other materials such as metals and traditional plastics, phenolic paper laminate shows superior chemical resistance. Metals are prone to corrosion, especially in the presence of acids and moisture, whereas many plastics may degrade or dissolve when exposed to strong solvents. This product, on the other hand, maintains its structural integrity and performance in such conditions, making it a reliable choice for applications requiring chemical resistance.

What Are the Common Applications of Phenolic Paper Laminate in Chemical Environments?

Given its chemical resistance, phenolic paper laminate is used in a variety of applications across multiple industries. Here are some common uses:

Electrical and Electronic Components

Phenolic paper laminate is extensively used in the electrical and electronics industry for making components such as switchboards, terminal boards, and insulating plates. These components often operate in environments where they might be exposed to chemicals. The chemical resistance of phenolic paper laminate ensures these components remain functional and safe over time.

Laboratory Work Surfaces

Laboratories often deal with a wide range of chemicals that can be highly corrosive. It is used to construct work surfaces and countertops in laboratories. These surfaces can withstand spills of various chemicals without deteriorating, making them ideal for laboratory environments.

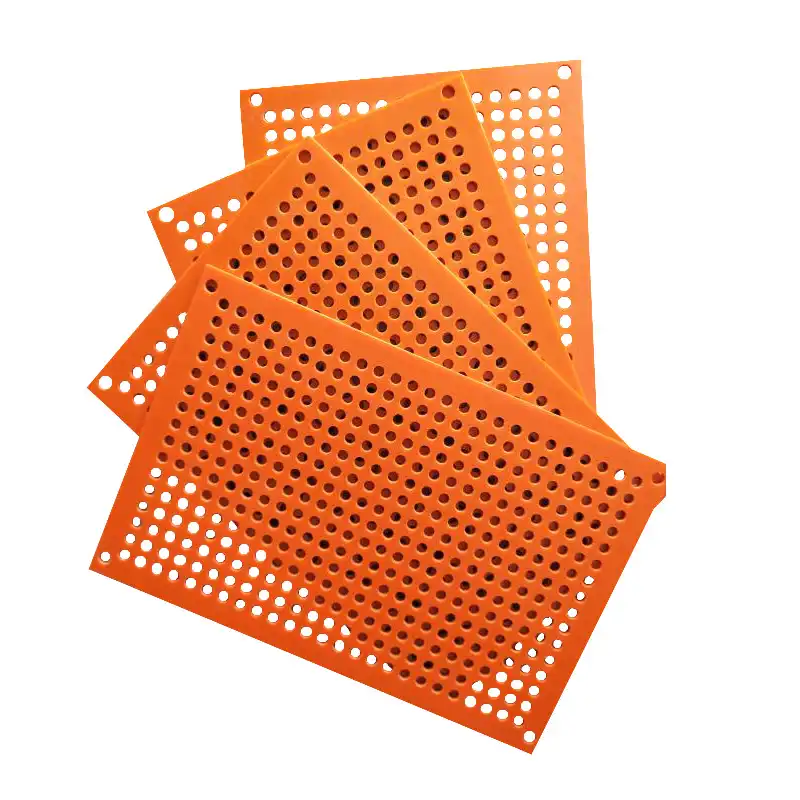

Industrial Equipment and Machinery

In industrial settings, machinery and equipment parts made from phenolic paper laminate can endure exposure to harsh chemicals. This includes gaskets, seals, and protective coverings. The chemical resistance of phenolic laminate ensures these parts have a long service life and maintain their performance even in challenging environments.

How Does Phenolic Paper Laminate Perform in Long-Term Chemical Exposure?

Long-term exposure to chemicals is a crucial factor to consider when evaluating the suitability of materials for certain applications. Phenolic paper laminate's performance over prolonged periods is a testament to its durability and resistance.

Durability and Maintenance

Phenolic paper laminate not only resists immediate chemical attack but also exhibits long-term durability. This makes it a cost-effective material in terms of maintenance and replacement. Surfaces and components made from phenolic paper laminate require minimal upkeep, reducing downtime and maintenance costs.

Case Studies and Industry Examples

Several industries have documented the long-term performance of the product in chemically aggressive environments. For example, in the chemical processing industry, phenolic laminate is used for lining tanks and vessels that store corrosive chemicals. These linings protect the structural integrity of the tanks, preventing leaks and failures over time.

In another instance, which is used in wastewater treatment plants. The material's resistance to a variety of chemicals, including those found in industrial effluents, ensures the longevity and reliability of treatment equipment.

Conclusion

Phenolic paper laminate's resistance to chemical corrosion makes it an invaluable material across various industries. Its inherent properties derived from phenolic resin, coupled with its long-term durability, ensure that it stands up to the challenges posed by chemical exposure. Whether in electrical components, laboratory surfaces, or industrial machinery, which provides a reliable and cost-effective solution.

References

1. Kor-Pak Corporation. (2022). A Complete Guide to Phenolic Laminates and Their Uses. Retrieved from [Kor-Pak](https://www.kor-pak.com).

2. Wilsonart. (2023). Chemical Resistant Laminate & Surfaces. Retrieved from [Wilsonart](https://www.wilsonart.com).

3. Emco Industrial Plastics. Phenolic Sheets & Rods. Retrieved from [Emco Plastics](https://www.emcoplastics.com).

4. Atlas Fibre. Phenolic Thermoset Composite Laminates. Retrieved from [Atlas Fibre](https://www.atlasfibre.com).