Can FR4 Epoxy Sheets withstand high temperatures?

2024-06-04 14:07:44

Can FR4 Epoxy Sheets withstand high temperatures?

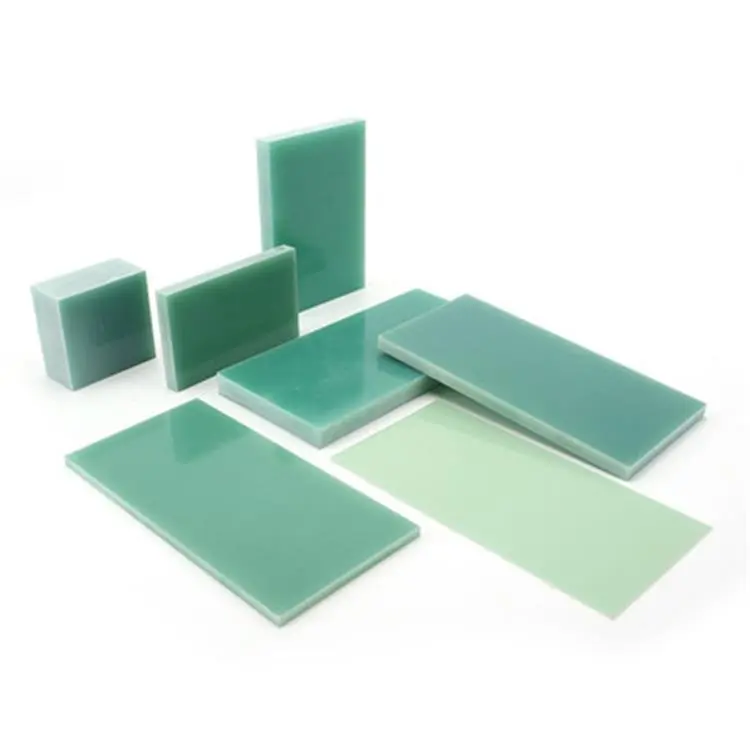

Epoxy Resin Sheets are widely utilized in electronic applications attributable to their outstanding mechanical strength, electrical protection properties, and fire opposition. Nonetheless, a basic perspective that warrants exhaustive investigation is their presentation when exposed to high temperatures. Diving into this theme requires an inside and out examination organized around key viewpoints that highlight their temperature versatility.

Temperature Limits and Stability of FR4 Epoxy Sheets

FR4 epoxy sheets are explicitly intended to work ideally inside a characterized temperature range, regularly going from - 40°C to 130°C. This temperature resilience is a key property that guarantees the material keeps up with its mechanical strength and electrical protection properties, pursuing it a flexible decision for a wide exhibit of utilizations crossing from customer hardware to aviation parts. The capacity of FR4 to maintain its uprightness inside this assigned temperature range highlights its dependability and appropriateness for different enterprises where reliable execution is fundamental.

In any case, it is pivotal to take note of that when exposed to temperatures surpassing 130°C, FR4 might start to go through warm corruption. This corruption cycle can possibly influence the material's mechanical qualities and undermine its electrical protection limit. In that capacity, working Epoxy Resin Sheets past the predefined temperature cutoff can bring about a decrease in execution and unwavering quality, presenting dangers to the usefulness and life span of parts or frameworks using this material. Understanding the temperature limits of FR4 epoxy sheets is crucial in successfully integrating them into applications where warm circumstances assume a critical part.

Impact of High Temperatures on FR4

Openness to temperatures outperforming their assigned limit can prompt outstanding changes in FR4 sheets. Raised warm circumstances can possibly start mellowing or distortion of the material, applying an immediate effect on its general strength and firmness. This penchant for mellowing and distortion highlights the basic significance of sticking to the endorsed temperature cutoff points to maintain the mechanical uprightness and dependability of FR4 in different applications.

The warm extension qualities of FR4 become a relevant thought while experiencing high temperatures. The material's reaction to warm extension can influence its layered strength, especially inside firmly stuffed electronic congregations. Unnecessary warm development can possibly present layered varieties or twists, which might think twice about exact arrangement and interconnection of electronic parts, subsequently presenting difficulties to the dependable activity of electronic frameworks.

Thermal Management and Design Considerations

Integrating FR4 Epoxy Sheet into plans expected for conditions described by high temperatures requires a careful way to deal with warm administration. The particular intensity of FR4 arises as a critical consider this specific situation, applying a huge effect on the material's ability to ingest, hold, and delivery heat. Understanding and utilizing the particular intensity properties of FR4 are fundamental for designing arrangements that empower the material to persevere through temperature varieties while maintaining ideal usefulness, especially in applications, for example, printed circuit sheets (PCBs) where productive intensity dispersal is essential for deflecting overheating and expected harm.

Proficient warm administration systems are instrumental in improving the flexibility of FR4 parts inside high-temperature conditions. By exhaustively tending to warm assimilation, maintenance, and dissemination attributes, architects can devise plans that relieve the unfriendly impacts of warm weight on FR4, in this way advancing supported functional unwavering quality. Besides, in PCB applications, where heat dissemination is a basic concern, key warm administration measures can work with the viable dispersal of intensity created during activity, protecting against unfavorable temperature heightening and saving the respectability of the electronic framework.

Comparing FR4 to Other High-Temperature Materials

Despite the fact that FR4 shows flexibility and viability inside its assigned temperature range, explicit high-temperature applications might call for materials with raised warm edges to guarantee ideal execution and unwavering quality. In situations where the working circumstances surpass the abilities of FR4, architects and fashioners frequently investigate choices with higher glass-change temperatures to satisfy the needs of additional thorough warm conditions.

Polytetrafluoroethylene (PTFE) is a remarkable illustration of a material that offers increased warm strength, portrayed by significantly higher glass-progress temperatures going from 160°C to 280°C. This distinctive element positions PTFE as a great option for applications requiring extraordinary warm perseverance, for example, rapid or high-recurrence printed circuit sheets (PCBs) working in requesting warm conditions.

Practical Applications of FR4 in High-Temperature Settings

FR4 Epoxy Sheet notwithstanding its requirements at extremely high temperatures, remains generally embraced across ventures inferable from its balanced and adjusted properties. Its flexible nature positions it as a material of decision in a variety of utilizations inside auto parts, aviation design, and modern hardware, where it reliably conveys unwavering quality across different warm circumstances. This versatility highlights FR4's importance in empowering the exhibition and life span of basic frameworks and parts in requesting functional conditions.

One of the essential variables adding to the far reaching reception of FR4 is its innate fire resistant attributes, which are instrumental in upgrading security in different applications. This trait guarantees that FR4 shows flexibility notwithstanding potential fire dangers, making it especially reasonable for wellbeing basic settings and applications where openness to intensity and flares is a common concern. The material's penchant for moderating fire gambles lines up with the rigid wellbeing prerequisites pervasive in businesses, for example, auto, aviation, and modern assembling, further cementing its remaining as a favored decision for guaranteeing functional security and dependability.

Conclusion

In conclusion, Epoxy Resin Sheets offer robust performance within their specified temperature range of -40°C to 130°C. While suitable for a myriad of applications, scenarios requiring exposure to higher temperatures may necessitate alternative materials with higher thermal tolerances. Understanding the specific requirements and environmental conditions of your application will guide the appropriate selection of materials.

Contact Us

Are you looking for a professional manufacturing supplier with a proven track record? Look no further! We are a GMP-certified factory with a large inventory, complete certifications, and we support OEM services. With fast delivery, secure packaging, and extensive testing capabilities, we invite global buyers to explore cooperation opportunities. Reach out to us at info@jhd-material.com for partnership discussions and to learn how our high-quality products can meet your needs.

_1732777843529.webp)