Can a Flame Resistance FR4 Fiber Glass Laminate Sheet be used for structural applications?

2024-06-07 16:33:05

Introduction

In the realm of structural engineering, the quest for materials that offer both robustness and fire resistance is perpetual. Among the contenders in this arena is the Flame Resistance FR4 Fiber Glass Laminate Sheet, a material renowned for its durability and ability to withstand high temperatures. In this article, I delve into the question: Can a Flame Resistance FR4 Fiber Glass Laminate Sheet truly be utilized for structural applications? Through a comprehensive examination of its properties, applications, and industry standards, we aim to provide clarity on this intriguing topic.

Understanding Flame Resistance FR4 Fiber Glass Laminate Sheet

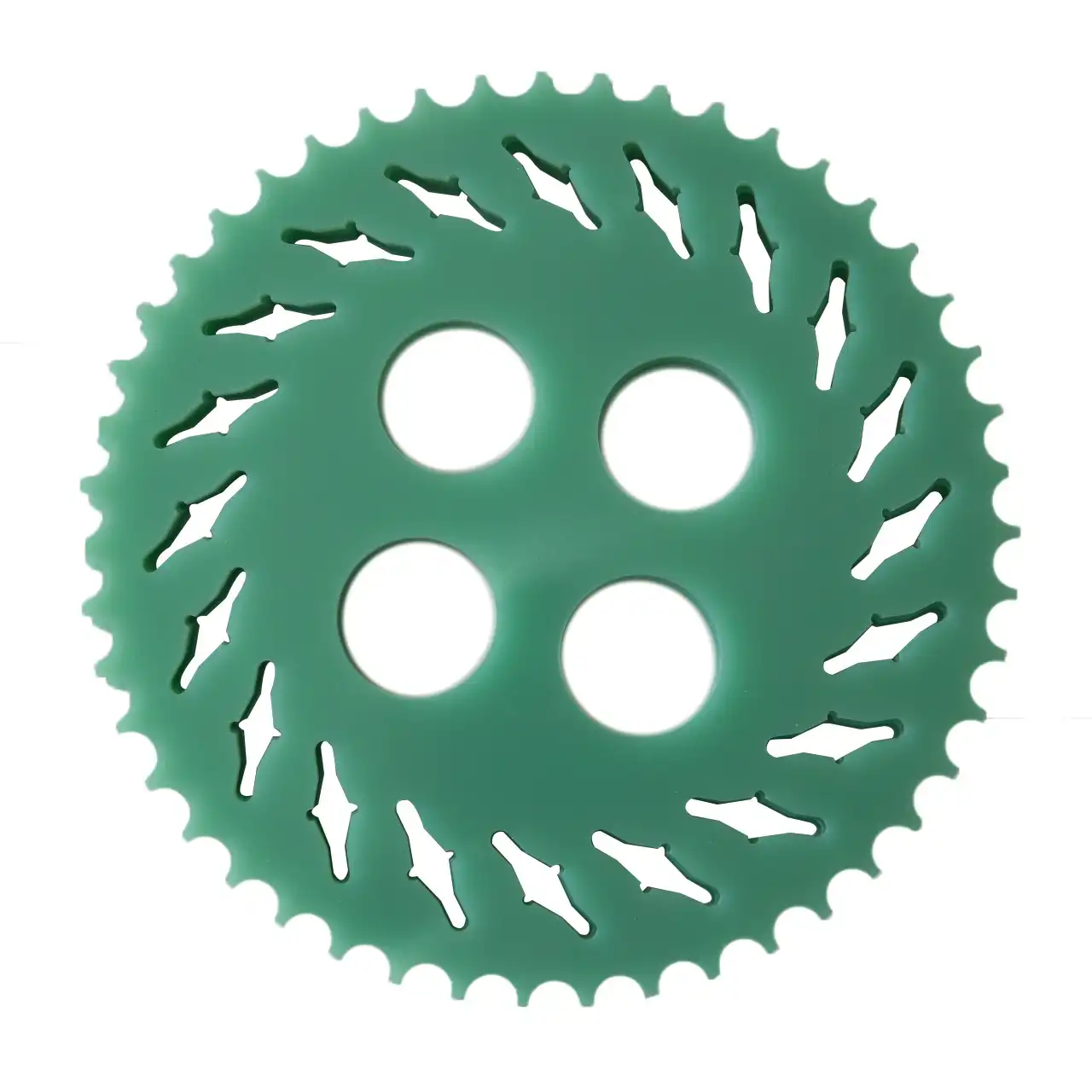

Before we delve into its structural potential, let's grasp the essence of Flame Resistance FR4 Fiber Glass Laminate Sheet. Flame Resistance FR4 Fiber Glass Laminate Sheet denotes a grade of material that adheres to specific fire resistance standards. Composed of woven fiberglass cloth impregnated with epoxy resin, FR4 boasts exceptional mechanical strength, electrical insulation properties, and, crucially, resistance to flames and heat.

Properties of Flame Resistance FR4 Fiber Glass Laminate Sheet

The suitability of FR4 for structural applications hinges on its key properties. Firstly, its mechanical strength is noteworthy, making it adept at bearing loads and resisting deformation. Secondly, its electrical insulation properties render it indispensable in electronic devices and systems. Thirdly, and perhaps most pertinent to our inquiry, is its flame resistance. FR4 exhibits remarkable resistance to ignition and propagation of flames, owing to the inherent properties of its constituent materials and the specific manufacturing processes employed.

Applications of Flame Resistance FR4 Fiber Glass Laminate Sheet

The versatility of FR4 extends across various industries, each capitalizing on its unique attributes. In the realm of electronics, Flame Resistance FR4 Fiber Glass Laminate Sheet serves as the substrate for printed circuit boards (PCBs), ensuring reliable performance amidst electrical currents and heat. Moreover, its flame resistance makes it a preferred choice in applications where fire safety is paramount, such as aerospace components, automotive parts, and electrical enclosures. However, its potential for structural applications warrants closer scrutiny.

In addition to its use in electronics and fire-resistant applications, FR4 fiber glass laminate sheet can also be utilized in structural components where strength and durability are key requirements. For example, in the construction industry, FR4 can be used as a reinforcing material in composite structures, providing additional rigidity and stability. Its high mechanical strength allows it to support heavy loads, while its resistance to moisture and chemicals makes it suitable for use in harsh environments.

Furthermore, in the marine industry, FR4's water resistance and ability to withstand corrosive elements make it an ideal material for boat building and marine equipment. It can be used to construct lightweight, durable panels for boats, ensuring both safety and performance on the water. The flame-resistant properties of FR4 also contribute to the overall safety of marine vessels, reducing the risk of fire during operation.

In summary, the applications of flame-resistant FR4 fiber glass laminate sheet extend beyond electronic devices and fire-safety critical components to include structural and marine uses. Its combination of strength, durability, and environmental resistance makes it a valuable material in various industries, enhancing performance and safety in diverse applications.

Assessing Structural Suitability

The pivotal question remains: Can FR4 Fiber Glass Laminate Sheets be deemed structurally sound? While FR4 exhibits commendable mechanical strength and resilience, its application in load-bearing structures necessitates adherence to stringent standards and regulations. Structural engineering mandates rigorous testing and certification to ascertain the material's suitability for specific loads, environmental conditions, and safety requirements.

Standards and Certifications

In the pursuit of structural integrity, adherence to industry standards is non-negotiable. For FR4 Fiber Glass Laminate Sheets, compliance with standards such as those set forth by the National Fire Protection Association (NFPA) and the American Society for Testing and Materials (ASTM) is imperative. These standards encompass criteria for flame resistance, mechanical properties, and overall performance, providing a framework for evaluating the material's suitability for structural applications.

Challenges and Considerations

Despite its inherent strengths, FR4 presents challenges and considerations when contemplating structural use. One such consideration is its brittleness, which may compromise its ability to withstand dynamic loads and impacts. Additionally, factors such as moisture absorption, temperature fluctuations, and long-term durability must be carefully evaluated to mitigate potential risks and ensure the longevity of structural components.

Case Studies and Success Stories

While the structural application of FR4 Fiber Glass Laminate Sheets may raise eyebrows, notable case studies offer insights into its viability. From the construction of lightweight, fire-resistant facades to the fabrication of durable, corrosion-resistant structural elements, FR4 has demonstrated its mettle in diverse architectural and engineering endeavors. These success stories underscore the material's potential when utilized judiciously and in accordance with established standards and best practices.

Conclusion

In conclusion, the question of whether Flame Resistance FR4 Fiber Glass Laminate Sheet can be used for structural applications warrants nuanced consideration. While the material possesses commendable properties such as mechanical strength and flame resistance, its suitability for structural use hinges on adherence to rigorous standards, thorough testing, and careful engineering considerations. By navigating these challenges with prudence and expertise, FR4 holds promise as a viable option for enhancing structural integrity while prioritizing fire safety.

Contact us

For inquiries about Flame Resistance Flame Resistance FR4 Fiber Glass Laminate Sheet and other industrial materials, contact us at info@jhd-material.com. As a professional manufacturing supplier with a GMP factory, large inventory, complete certificates, and support for OEM requirements, we ensure fast delivery, tight packaging, and comprehensive testing support. Join hands with us to elevate your projects and attract global buyers seeking quality and reliability.

References

1. National Fire Protection Association (NFPA)

2. American Society for Testing and Materials (ASTM)

3. "FR-4" - Wikipedia

4. "Flame Retardant 4 (FR4) PCB Material Properties" - PCB Directory

5. "Fire-resistant materials for building structures: a state-of-the-art review" - Fire Technology, Springer

_1747991245292.webp)