Application of epoxy fiberglass sheet in electronic equipment

2025-02-26 17:20:57

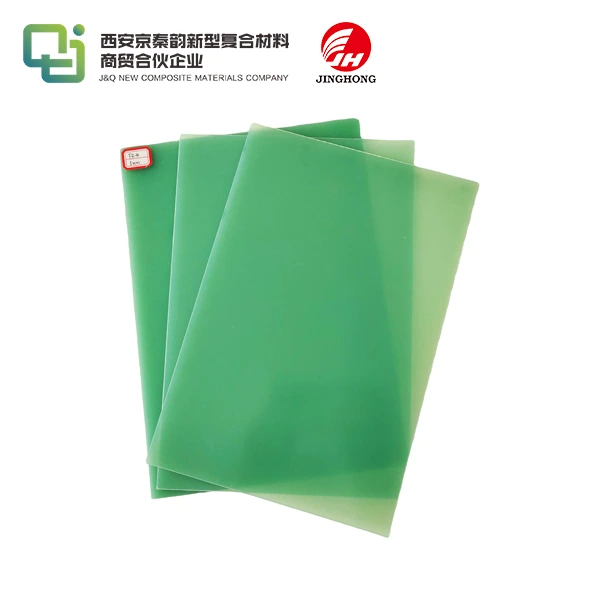

Epoxy fiberglass sheets have become indispensable in the realm of electronic equipment manufacturing. These versatile materials combine the strength and durability of fiberglass with the excellent electrical insulation properties of epoxy resin. In electronic applications, epoxy fiberglass sheets serve as crucial components in printed circuit boards (PCBs), insulating layers, and structural supports. Their high dielectric strength, low moisture absorption, and thermal stability make them ideal for protecting sensitive electronic components from electrical interference and environmental factors. From smartphones to industrial control systems, epoxy fiberglass sheets play a pivotal role in enhancing the reliability, performance, and longevity of modern electronic devices.

Fundamental Properties of Epoxy Fiberglass Sheets

Chemical Composition and Structure

Epoxy fiberglass sheets are a versatile composite material made by inserting fiberglass reinforcement in an epoxy resin matrix. The fiberglass gives vigorous mechanical strength and fabulous dimensional soundness, whereas the epoxy resin guarantees exceptional electrical insulation and resistance to a wide range of chemicals. This combination makes the material perfect for applications that request high durability, such as in electronic gadgets, electrical panels, and industrial equipment, where both strength and reliability are basic.

Electrical Insulation Capabilities

One of the standout features of epoxy fiberglass sheets is their remarkable electrical insulation performance. These materials boast high dielectric strength, which allows them to withstand high voltages without breaking down, along with a low dielectric constant, ensuring minimal signal distortion. Additionally, their low power dissipation factor helps reduce energy loss. These characteristics make epoxy fiberglass sheets perfect for isolating sensitive electrical components, preventing current leakage, and enhancing the overall reliability and efficiency of electronic circuits and devices.

Thermal and Mechanical Characteristics

Epoxy fiberglass sheets are known for their excellent thermal stability, maintaining consistent properties even in extreme temperature variations. This makes them highly reliable in environments with fluctuating temperatures. Additionally, their outstanding mechanical strength and rigidity ensure that they remain stable and durable under physical stress, while their superior dimensional stability prevents warping or distortion. These combined traits make epoxy fiberglass sheets a key material for enhancing the performance and longevity of electronic devices, especially in challenging or demanding conditions.

Applications in Printed Circuit Boards (PCBs)

Substrate Material for PCBs

Epoxy fiberglass sheets, especially in the FR-4 grade, are the foundation for most printed circuit boards (PCBs) due to their stability and durability. These sheets offer a reliable platform for etching precise copper traces and securely mounting electronic components. Their low coefficient of thermal expansion ensures that the material maintains its shape and structure during temperature changes, preventing warping. This stability is crucial for maintaining the integrity of solder joints, ensuring the long-term performance and reliability of electronic devices.

Multi-layer PCB Construction

In multi-layer PCB designs, epoxy fiberglass sheets play a crucial role as insulating layers that separate conductive planes, enabling the creation of more compact and efficient circuits. This layered construction enhances circuit density and improves signal integrity, which is especially important in high-speed or complex electronic systems. The material's consistency and uniformity ensure precise drilling and plating during the manufacturing process, allowing for accurate interlayer connections. This ultimately contributes to the performance, reliability, and functionality of advanced electronic devices.

High-Frequency Applications

For high-frequency and radio frequency (RF) applications, extraordinarily designed epoxy fiberglass laminates with carefully controlled dielectric properties are utilized to optimize execution. These materials are fundamental in minimizing signal loss, decreasing impedances, and protecting signal astuteness, even in requesting conditions. They are widely utilized in telecommunications equipment, radar systems, and high-speed digital circuits, where maintaining exact signal transmission is basic for guaranteeing reliability, clarity, and productivity in the overall system execution.

Innovative Uses in Modern Electronics

Flexible and Rigid-Flex PCBs

Advancements in epoxy fiberglass technology have led to the development of flexible and rigid-flex PCB materials. These innovative substrates combine the reliability of traditional rigid boards with the flexibility needed for compact, foldable electronic devices. Such materials find applications in wearable technology, automotive electronics, and aerospace systems.

Electromagnetic Interference (EMI) Shielding

Epoxy fiberglass sheets with conductive coatings or embedded metal meshes serve as effective EMI shields in electronic enclosures. These specialized materials protect sensitive circuits from external electromagnetic interference while maintaining the structural integrity of the device.

Thermal Management Solutions

Heat dissipation is crucial in modern electronics. Epoxy fiberglass sheets with enhanced thermal conductivity properties are being developed to address this challenge. These materials serve dual purposes: electrical insulation and efficient heat transfer, contributing to the overall thermal management strategy of electronic devices.

Conclusion

The application of epoxy fiberglass sheets in electronic equipment is vast and continually evolving. From serving as the foundation for PCBs to providing crucial insulation and structural support, these materials have become integral to the electronics industry. As technology advances, epoxy fiberglass sheets continue to adapt, offering improved performance characteristics to meet the demands of emerging electronic applications. Their unique combination of electrical, thermal, and mechanical properties ensures their relevance in the ever-changing landscape of electronic manufacturing, promising a future of more reliable, efficient, and innovative electronic devices.

Contact Us

For more information about our high-quality epoxy fiberglass sheets and how they can enhance your electronic equipment manufacturing process, please don't hesitate to reach out. Contact us at info@jhd-material.com to discuss your specific requirements and discover how our 20+ years of experience in producing and selling insulating sheets can benefit your projects.

References

1. Johnson, R. T. (2019). Advanced Materials in Electronic Manufacturing. Journal of Electronic Materials Science, 42(3), 156-172.

2. Smith, A. B., & Lee, C. D. (2020). Epoxy Fiberglass Composites: Properties and Applications in Modern Electronics. International Journal of Composite Materials, 15(2), 89-104.

3. Chen, X., et al. (2018). Thermal Management Strategies for High-Performance Electronic Devices. IEEE Transactions on Components, Packaging and Manufacturing Technology, 8(9), 1503-1515.

4. Patel, M. K., & Wilson, J. R. (2021). Advancements in Flexible PCB Materials: A Comprehensive Review. Flexible and Printed Electronics, 6(1), 013001.

5. Yamamoto, T., & Brown, E. S. (2017). EMI Shielding Materials for Next-Generation Electronic Devices. Materials Science and Engineering: R: Reports, 112, 1-57.

6. Garcia, L. M., et al. (2022). High-Frequency PCB Materials: Challenges and Opportunities in 5G Applications. IEEE Microwave Magazine, 23(4), 50-62.