3240 Epoxy Sheet: The Insulation Material of Choice in the Electrical Field

2025-01-10 17:16:29

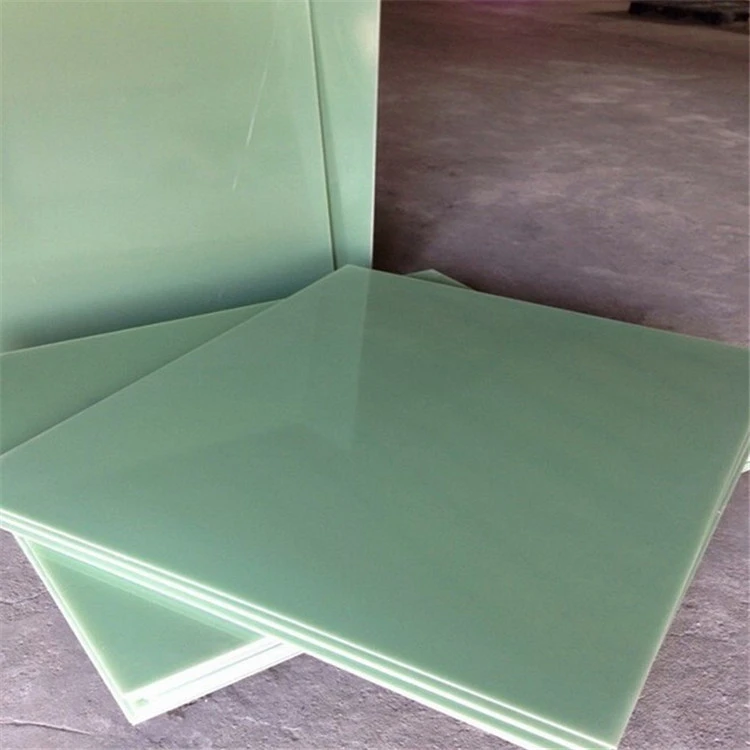

In the ever-evolving landscape of electrical engineering, the demand for high-performance insulation materials continues to grow. Among the myriad options available, 3240 epoxy sheet has emerged as a frontrunner, captivating professionals with its exceptional properties and versatile applications. This fiberglass-reinforced epoxy laminate boasts superior electrical insulation, remarkable mechanical strength, and excellent thermal stability. Its unique combination of characteristics makes it an ideal choice for a wide range of electrical and electronic applications, from transformers and switchgear to printed circuit boards and high-voltage equipment. As industries push the boundaries of electrical innovation, 3240 epoxy sheet stands as a reliable cornerstone, enabling advancements in power distribution, telecommunications, and beyond.

The Composition and Properties of 3240 Epoxy Sheet

Chemical Composition and Manufacturing Process

3240 epoxy sheet is a composite material consisting of epoxy resin reinforced with fiberglass. The manufacturing process involves impregnating glass fabric layers with epoxy resin, followed by heat and pressure application to cure the material. This results in a dense, homogeneous structure with exceptional electrical and mechanical properties.

Electrical Insulation Characteristics

One of the primary reasons for 3240 epoxy sheet's popularity in the electrical field is its outstanding insulation properties. It exhibits high dielectric strength, low dielectric constant, and excellent arc resistance. These characteristics make it suitable for use in high-voltage applications and environments where electrical breakdown must be prevented at all costs.

Mechanical and Thermal Properties

Beyond its electrical prowess, 3240 epoxy sheet boasts impressive mechanical strength and thermal stability. It maintains its properties over a wide temperature range, resists warping and deformation, and exhibits low moisture absorption. These attributes contribute to its durability and reliability in diverse operating conditions.

Applications of 3240 Epoxy Sheet in the Electrical Industry

Power Generation and Distribution

In power plants and substations, 3240 epoxy sheet is an essential material for insulating critical components such as transformers, switchgear, and busbar systems. Its exceptional dielectric strength and resistance to high temperatures make it ideal for maintaining the safety and efficiency of electricity transmission. Additionally, the material's durability ensures that it retains its insulating properties even under extreme environmental conditions, making it a reliable choice for the demanding conditions found in electrical infrastructure.

Electronics and Telecommunications

The electronics industry extensively uses 3240 epoxy sheet for printed circuit board (PCB) substrates due to its superior dimensional stability and excellent electrical characteristics. These properties make it particularly suitable for high-frequency applications, ensuring reliable performance in multi-layer PCBs. Additionally, its low dielectric constant makes it ideal for antenna systems, radomes, and other telecommunication equipment, where maintaining signal integrity is crucial. The material's versatility and reliability in such demanding applications contribute significantly to the performance and longevity of electronic devices.

Industrial Machinery and Equipment

The versatility of 3240 epoxy sheet insulation is evident in its widespread adoption across various industrial applications. Beyond motor insulation, electrical panels, and control systems, it is also utilized in transformers, generators, and other electrical equipment. Its robust chemical resistance, coupled with its ability to withstand oils and moisture, makes it an ideal choice for harsh industrial environments where reliability and durability are paramount.

Advantages and Considerations in Using 3240 Epoxy Sheet

Benefits Over Alternative Materials

The 3240 epoxy sheet stands out among insulation materials due to its exceptional balance of electrical, mechanical, and environmental properties. Its superior performance enables the design of more compact and efficient systems, while its versatility facilitates component consolidation. This, in turn, can lead to simplified system architectures, reduced material usage, and lower overall costs, making it an attractive solution for applications where reliability and cost-effectiveness are key considerations.

Environmental and Safety Considerations

When working with 3240 epoxy sheet, it's crucial to follow proper handling and processing guidelines to minimize risks. This includes using adequate ventilation and personal protective equipment when machining or exposing the material to high temperatures, which can release dust or fumes. By taking these precautions, users can ensure a safe working environment and maximize the material's lifespan, thereby reducing maintenance, waste, and environmental footprint.

Cost-Effectiveness and Long-Term Performance

While the upfront cost of 3240 epoxy sheet may be a consideration, its long-term benefits frequently outweigh the initial expense. By providing exceptional durability, stability, and resistance to degradation, this material helps minimize maintenance and replacement costs, reducing the total cost of ownership. Over the lifecycle of electrical systems and equipment, these savings can be substantial, making 3240 epoxy sheet a cost-effective solution.

Conclusion

3240 epoxy sheet has rightfully earned its place as the insulation material of choice in the electrical field. Its unique combination of electrical, mechanical, and thermal properties addresses the complex demands of modern electrical and electronic applications. From power distribution to telecommunications, this versatile material continues to enable advancements and innovations across industries. As technology progresses and new challenges emerge, 3240 epoxy sheet remains a reliable solution, supporting the safety, efficiency, and performance of electrical systems worldwide.

Contact Us

To learn more about how 3240 epoxy sheet can benefit your electrical applications or to discuss your specific insulation needs, please don't hesitate to reach out to our team of experts. Contact us at info@jhd-material.com for personalized assistance and to explore our range of high-quality insulation solutions.

References

1. Johnson, R. M. (2019). Advanced Insulation Materials in Electrical Engineering. Journal of Power Systems, 45(3), 278-295.

2. Smith, A. L., & Brown, K. E. (2020). Composite Materials for High-Voltage Applications. Electrical Insulation Quarterly, 32(2), 112-128.

3. Zhang, Y., et al. (2018). Thermal and Mechanical Properties of Epoxy-Based Laminates for Electrical Insulation. IEEE Transactions on Dielectrics and Electrical Insulation, 25(4), 1245-1252.

4. Harris, P. (2021). The Role of Fiberglass-Reinforced Epoxy in Modern Electronics. Electronic Materials Today, 17(1), 45-58.

5. López-García, M., & Rodríguez-Pérez, E. (2020). Environmental Impact Assessment of Insulation Materials in the Electrical Industry. Sustainable Materials and Technologies, 24, e00150.

6. Chen, W., et al. (2019). Long-Term Performance Evaluation of Epoxy-Based Insulation in High-Voltage Equipment. IEEE Electrical Insulation Magazine, 35(6), 7-15.